A water-lubricated oil free screw air compressor is a machine that exclusively utilizes water, eliminating the need for any lubricating oil. This design prevents environmental pollution and emissions. The compressed air within the stainless steel cylinder body is cleansed by pure water. The maximum compression chamber temperature of the main engine does not exceed 50℃, the whole unit works at normal temperature, the compressed air temperature without cooling does not exceed 45℃, the water content is very low, all the unit parts work at normal temperature, extending the service life of the parts, improving the reliability, and the failure rate is low.

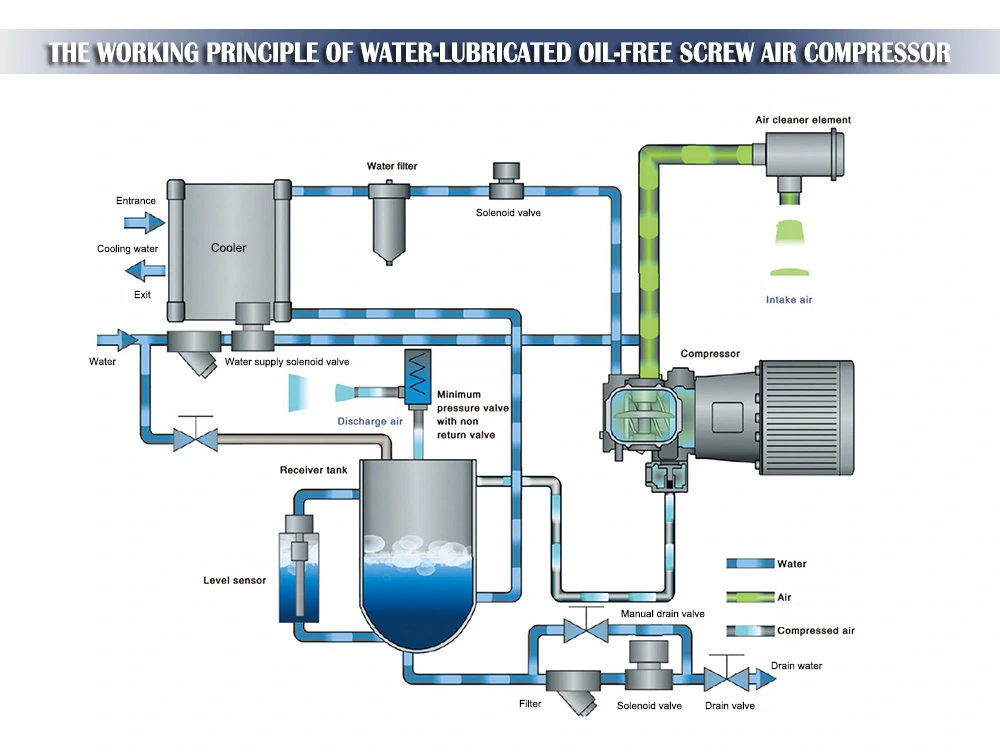

Working Principle of Water-Lubricated Oil-Free Screw Air Compressor:

1. Intake process:

The outside air enters the air inlet of the air compressor through the intake filter.

Near the air intake is a set of impellers that rotate to supercharge the air and feed it into the oil free screw air compressor.

2. Compression stage:

The air is directed to the oil free screw compressor. The oil free screw compressor is composed of two screws (one fixed and one movable).

When the screw is running, the movable screw achieves air compression with the help of the fixed screw.

3. Cooling stage:

The compressed air becomes hot and needs to be cooled by a cooling system.

A common way to do this is to use a water cooling system, in which water is circulated through a cooling pipe to help cool the compressed air.

4. Separation and drying:

The cooled air passes through a separator to separate the water and oil.

Moisture is then further removed from the air by drying systems, such as adsorption or condensing dryers.

5. Emission stage:

The dry, oil-free air after the final treatment is stored in a compressed air container for subsequent application scenarios.

Inside the container, there are usually discharge valves that release air into the service system as needed.

Through the above process, water-lubricated oil-free screw air compressors provide clean, efficient compressed air and are suitable for applications with high air quality requirements.

Understanding the oil free compressor working principle is essential to evaluating its performance. First, understanding its working principle can help you understand the core technology and design features of the compressor, so as to better judge whether it is suitable for your specific application needs. Secondly, understanding its working principle can allow you to more clearly evaluate the efficiency and energy consumption of the oil free rotary screw air compressor, ensuring that the purchased equipment is cost-effective in long-term use. In addition, a deep understanding of the working principle can also help you identify potential maintenance needs and failure points, so as to choose a more reliable product. By understanding the oil free compressor working principle, you can make more informed purchasing decisions. Finally, mastering the oil free air compressor working principle can provide you with valuable knowledge in subsequent operation and maintenance, extending the service life of the equipment and improving overall operational efficiency.

Oil-Free Operation: Water-lubricated oil-free screw air compressors are designed to operate without the use of oil lubrication. Traditional oil-lubricated compressors use oil for sealing and cooling, which can introduce oil contaminants into the compressed air. In contrast, the electric oil free air compressor eliminates the risk of oil contamination entirely, ensuring that the compressed air remains free of oil particles.

Elimination of Oil Carryover: Oil carryover, where trace amounts of oil escape into the compressed air, is a concern in oil-lubricated compressors. Water-lubricated oil-free screw compressors significantly reduce or entirely eliminate the risk of oil carryover, guaranteeing clean, oil-free compressed air.

Reduced Maintenance: Oil-free screw compressors require less maintenance compared to oil-lubricated counterparts. Without the need for oil changes, oil filter replacements, and oil separator maintenance, there is less opportunity for oil contamination to occur during routine servicing.

Cleaner End Products: In industries where compressed air comes into direct contact with products or processes, such as food and beverage manufacturing or pharmaceutical production, oil-free compressed air is essential to ensure the quality and safety of the end products. Water-lubricated oil free rotary screw compressors provide the necessary assurance that the compressed air will not introduce contaminants.

Water-lubricated oil-free screw compressors are efficient and low maintenance, utilizing water for lubrication. In contrast, dry oil-free compressors operate without water, making them suitable for applications where water is restricted or not desirable. Dry compressors offer clean air output with lower energy consumption, ideal for industries with stringent air quality requirements. Both types provide oil-free compressed air but differ in their lubrication methods. Water-lubricated compressors may require additional maintenance due to water systems. Dry screw compressor excels in environments where moisture contamination must be minimized, ensuring reliable operation and reduced environmental impact through water conservation. Ultimately, the choice between these compressors depends on specific needs, cost considerations, and environmental factors within the application context.

During the compression process, there is no need for lubricating oil, which is crucial for industries such as food and beverage, pharmaceuticals, electronics, and medical manufacturing, where petroleum pollution could be harmful to the final products.

The oil free rotary screw air compressor provides a clean and dry compressed air supply, reducing the risk of contamination during the production process

The oil free rotary screw compressor has fewer components that require maintenance, reducing downtime and maintenance costs.

These screw drive air compressors for sale are more environmentally friendly, as they eliminate the risk of oil leaks and the need for oil treatment.

Water-lubricated oil free screw air compressor has the same power, the same pressure compared to dry oil-free screw machine has a larger displacement, more energy saving